What's the difference between aluminium coil and sheet?

From the aerospace and automotive industries to construction, mechanical engineering, electronics and packaging, many sectors rely on a steady source of aluminium to continue smooth operations. At Alanod, we’ve been delivering high-quality aluminium solutions to clients around the world for over 40 years, offering both aluminium sheets and coils. One of the questions we’re asked most often is: Which option is right for my project? In this article, we’ll take a closer look at the key differences to help you decide which format best suits your needs.

Coil or sheet? Here's everything you need to know

While both aluminium coils and sheets are made from the same material, they serve different purposes depending on how they’re processed, stored, and applied. Understanding these differences will help you to determine the best fit for your specific application. Keep reading as we delve deeper into the following topics:

- Understanding aluminium coils and sheets

- Comparing aluminium coil vs sheets

- Choosing the right option for your project

Understanding aluminium coils and sheets

Before exploring the differences in cost, handling, finish, and more, it’s important to begin with the basics:

What is an aluminium sheet?

Aluminium sheets or plates are created by pressing and rolling aluminium under high pressure. Depending on the alloy used, different grades of aluminium can be made with specific properties for a range of applications. For example, 1000 Series’ pure’ aluminium offers high corrosion resistance and excellent electrical and thermal conductivity, so it is often used in food processing, electrical transmission applications and chemical storage.

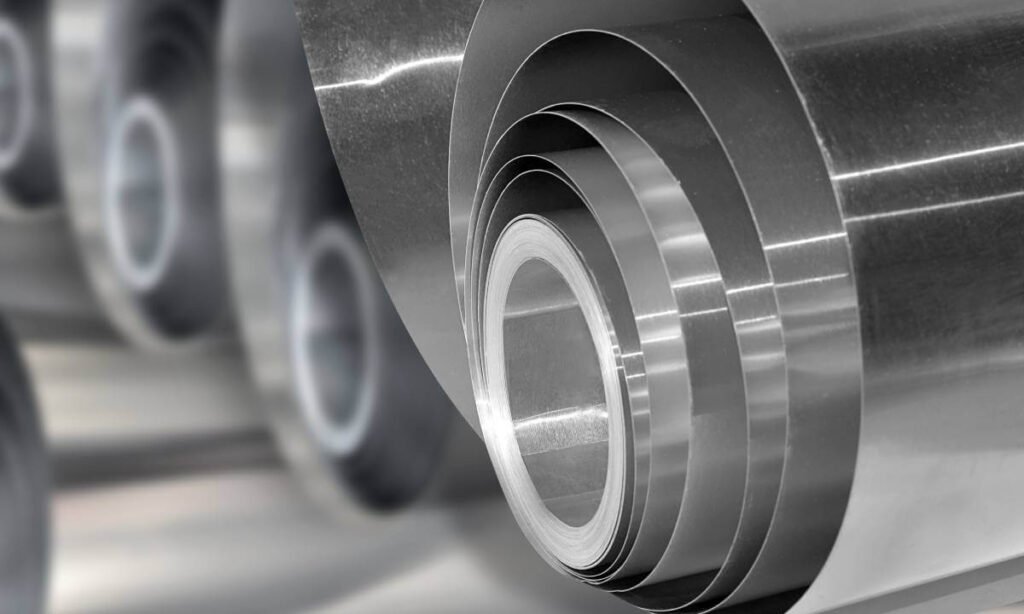

What is an aluminium coil?

Not surprisingly, as the name implies, the aluminium comes coiled around a hollow cylinder and depending on the application, the roll can be pre-painted, heat-treated, etc. Coils are highly durable and used across various industries, including construction, automotive, electronics, pharmaceutical, manufacturing, and food services.

Comparing aluminium coil vs sheets

The main difference between aluminium coils and sheets is their thickness and, of course, their appearance. Aluminium coils are flat sheets rolled into a coil, typically thinner than 0.6mm. In contrast, aluminium sheets arrive flat and have much more versatility in terms of thickness, available in 0.5mm to 6mm. More key differences include the following:

| Feature | Aluminium Coil | Aluminium Sheet |

|---|---|---|

| Handling | Best suited to high-volume operations as it will require uncoiling machinery before it can be coated, cut or bent. | Easy to transport and use manually, so it is ideal for smaller-scale projects. |

| Cost | Aluminium coil is generally purchased in bulk, which offers a lower cost per metre and less waste in automated systems. | Sheet aluminium is the most cost-effective option for small-scale or one-off use. |

| Sizing | As they are a continuous roll of aluminium, coils are more flexible in terms of sizing and can be cut to any length based on demand. | Sold as flat, pre-cut panels but can still be trimmed or cut down to smaller, precise dimensions. |

| Finish | Typically finished during the coiling process with options like anodising and lacquering. | Can be pre-finished if required, but this step is generally done after cutting. |

| Applications | An excellent option for industrial production such as roofing, cladding and vehicle panels. | Most commonly used for fabrication, construction, signage and retail. |

| Storage | As aluminium coils arrive as rolls, they are much easier to store. | Flat storage will be required for sheets to avoid warping. |

In terms of durability, when compared side by side at the same thickness, aluminium coils and sheets offer the same level of strength and longevity. Their robustness from then onwards depends on the coating added. You can learn more about the different finishing methods available for aluminium and their benefits in our previous article.

Choosing the right option for your project

Determining whether an aluminium coil or sheet is the best match for your project is relatively straightforward. Suppose you’re handling large-scale or continuous production. In that case, aluminium coils are the best option as they are ideal for automated systems where material is fed, cut or formed on the go. Sheets, on the other hand, are suited to smaller or custom projects where the material is used in pre-cut lengths or manually handled.

At Alanod, we tailor our orders to meet a wide range of customer demands, including the following:

Alanod Aluminium Coils:

- We ensure extremely tight tolerances on rolls and slip coils with minimal edge bow so they don’t jam whilst undergoing tooling.

- We offer a variety of coil products, including decorative finishes (brushed and coloured and mirror in colours), reflective finishes (products for lighting, UV reflection) and automotive specialist brush finishes.

- A variety of coil thicknesses (from 0.3 mm to 1mm in stock) and diameters (coil inside diameters 400mm up to 500mm) are available, from 50kg to 3.5 tonnes.

Alanod Aluminium Sheets:

- We offer a good flatness quality, even on large sheets up to 3.5m long.

- From 10 sheets upwards, as long as the metal is in stock, we can provide it.

- If extra surface scratch protection is needed as the sheets are handled, we can apply plastic films on one or both sides during the slitting process.

Ready to get started? Contact our technical team today

Whether you’re working on large-scale industrial production or a custom fabrication project, understanding the difference between aluminium coils and sheets is essential to achieve the best results. In short, coils offer flexibility and efficiency for continuous processes, while sheets provide convenience and ease for ready-to-use applications.

If you would like to discuss your project in more detail, feel free to contact our specialist team. We’re here to support you with technical advice and high-quality aluminium solutions, regardless of the scale of your project or supply needs.