Mill finish aluminium: Definition, benefits and applications

When it comes to aluminium, the term mill finish often surfaces in discussions about natural, untreated metal. But what is it, and how can it be used? Having spent more than 40 years supplying aluminium globally, raw aluminium has grown in popularity amongst our clients. Its natural form offers a cost-effective and versatile option with many manufacturing, construction and design advantages. In this article, we’ll explore mill finish aluminium, its benefits, and the industries that rely on its durability and adaptability.

Unlocking the potential of mill finish aluminium for your project

From the flagship Michael Kors store in Shanghai to Fulton Station in New York, we’ve been proud to supply our specialised metal surfaces for hundreds of remarkable projects. But beyond our signature finishes, we also offer raw, untreated aluminium – a versatile material with unique benefits and countless applications. Discover more below.

- What is mill finish aluminium?

- What does a mill finish look like?

- What are the benefits?

- How can it be used?

- What other finishes are available?

What is mill finish aluminium?

Mill finish aluminium refers to aluminium that has been extruded, rolled or cast and then left in its raw, untreated state. It hasn’t been finished with any surface treatments, such as anodising or lacquering, making it the most basic type of aluminium. A mill finish is typically used when cost-effectiveness is prioritised over aesthetics, for example, for roofing components or to produce packaging.

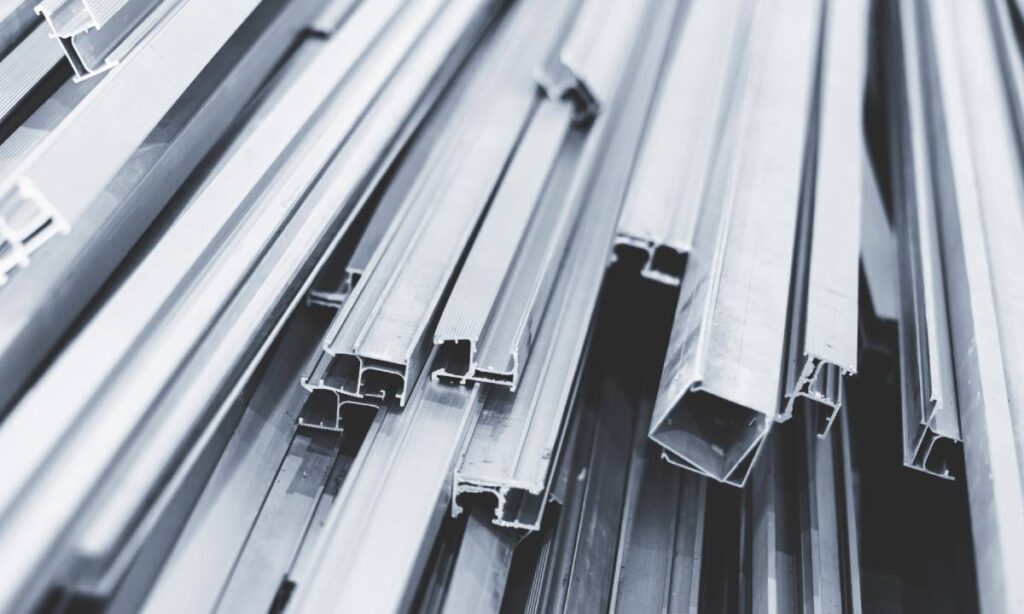

What does a mill finish look like?

As a mill finish means the aluminium has no protective or decorative coating, you can expect a matte finish with a rougher texture than other metal surfaces. It generally has only a slightly reflective surface with visible marks from the manufacturing process, whether it be lines, streaks or imperfections (i.e. die and tooling marks).

It isn’t uncommon for mill-finished aluminium to be confused with a brushed finish, and while both have a natural appearance, there are key differences. As mentioned above, mill-finished surfaces are completely untouched, whereas a brush finish aluminium has been mechanically abraded to remove these imperfections and create a smooth, even finish.

What are the benefits?

While mill finish aluminium may not look as aesthetic as its treated counterparts, it remains a sturdy, reliable and affordable material used across many industrial and commercial settings. More benefits include the following:

Cost-effective: As mill finish aluminium requires minimal processing and no additional surface treatments, it remains one of the cheapest options, ideal for applications where a natural, untreated surface is favoured.

Easy to fabricate: Aluminium is innately malleable (can be hammered or pressed into shape without cracking) and ductile (able to be drawn out into a thin wire), so when left raw, it becomes easier than ever to bend, form and shape during fabrication processes.

Corrosion resistant: Mill finish aluminium will naturally form an oxide layer when exposed to air; this acts as a protective barrier against further oxidation and corrosion, even in harsh environments.

Low maintenance: Following on from the above, the natural protective layer on mill finish aluminium means it requires little to no maintenance, unlike its alternatives, which may need regular painting or galvanising to prevent rust.

Lightweight material: Aluminium is around one-third the density of steel or copper, making it an inherently lightweight material. When it comes to a mill finish, the lack of surface treatment means no extra weight has been added, allowing for easy application.

100% recyclable: Much like all aluminium, surfaces with a mill finish can be recycled indefinitely without losing their natural qualities. They are melted down and reused for many different applications.

How can it be used?

Mill finish aluminium is widely used in applications when aesthetics and surface protection are not the main priority. It’s ideal for functional and industrial uses, such as:

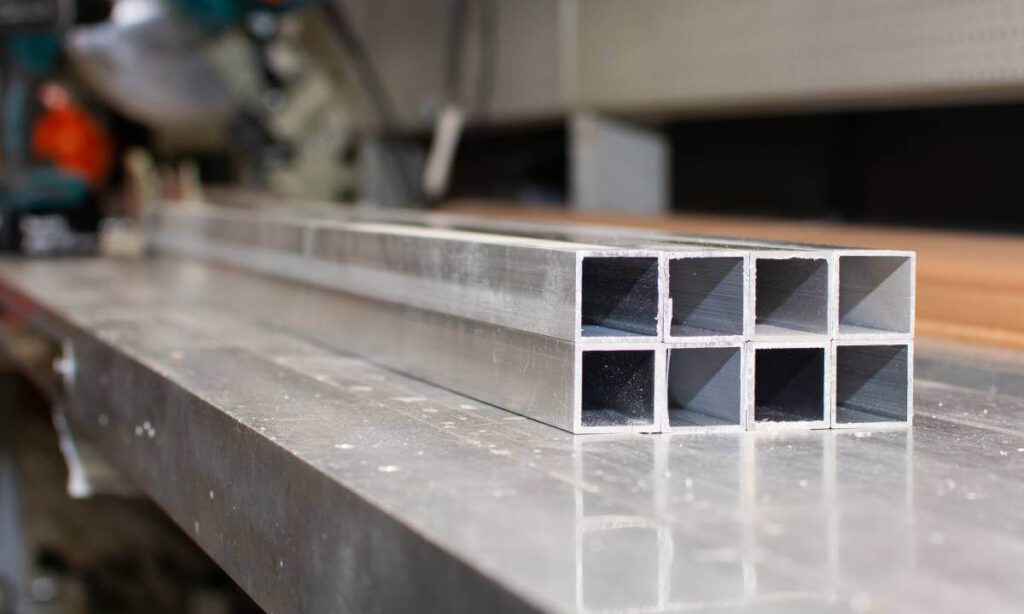

Construction: Mill finish aluminium is regularly used as a base material in construction, as well as for beams, frames and supports in buildings. It’s also a great option for guttering and flashings.

Manufacturing and industrial: As aluminium is strong yet lightweight and easy to cut or bend, it is commonly used for equipment parts or for storage tanks and containers.

Automotive and transport: From vehicle body panels to aerospace components and marine applications, mill finish aluminium is used across the automotive and transport sectors.

Food and packaging: Not only is mill finish aluminium used for disposable foil containers, but it’s often the base for cooking and baking trays before additional coatings are applied.

What other finishes are available?

If you are looking for a smoother, more uniform, and aesthetically pleasing finish on aluminium, there are many options available to tailor its appearance to your needs. At Alanod, we offer both anodising and lacquering alongside raw, untreated aluminium; here is what to expect from each:

Anodised aluminium: Aluminium that has been anodised has undergone an electrochemical process to alter its appearance with a decorative oxide layer. Available in many different colours, anodised aluminium has a metallic or two-tone effect and can be customised with a matte, mirrored or satin finish. Aside from aesthetics, anodising also creates a hardened, protective layer over the aluminium, making it resistant to wear, scratches, abrasion and corrosion.

Lacquered aluminium: During the lacquering process, a clear or coloured lacquer is applied to the aluminium before being cured in a specialised oven to harden the surface. There are endless colour options available when choosing lacquering, along with soft, textured and high-gloss finishes. As lacquering only involves applying a coating, it is generally a more cost-effective alternative to anodising.

If you would like to learn more about the different finishing methods on the market, take a look at our previous article or feel free to contact us to discuss your upcoming projects in more detail.

Explore mill finish aluminium with Alanod

While mill finish aluminium may be raw and untreated, its versatility, durability and cost-effectiveness certainly make it a valuable choice across many industries. From construction to manufacturing, this material offers a practical solution for those seeking strength and adaptability over polished aesthetics.

If you’re considering using mill finish aluminium in your next project or are looking for a long-term supplier, do not hesitate to contact our team at Alanod. With decades of experience, we specialise in high-quality aluminium supply, whether a single sheet or high-volume production run.