Taking reflective surfaces to the next level

We all know that aluminium is a versatile material, but when the surface is treated to make it reflective, a doorway to a whole new world of opportunity is opened. Here are some of the ways that reflective matt and gloss aluminium is being used to redefine the world we live in.

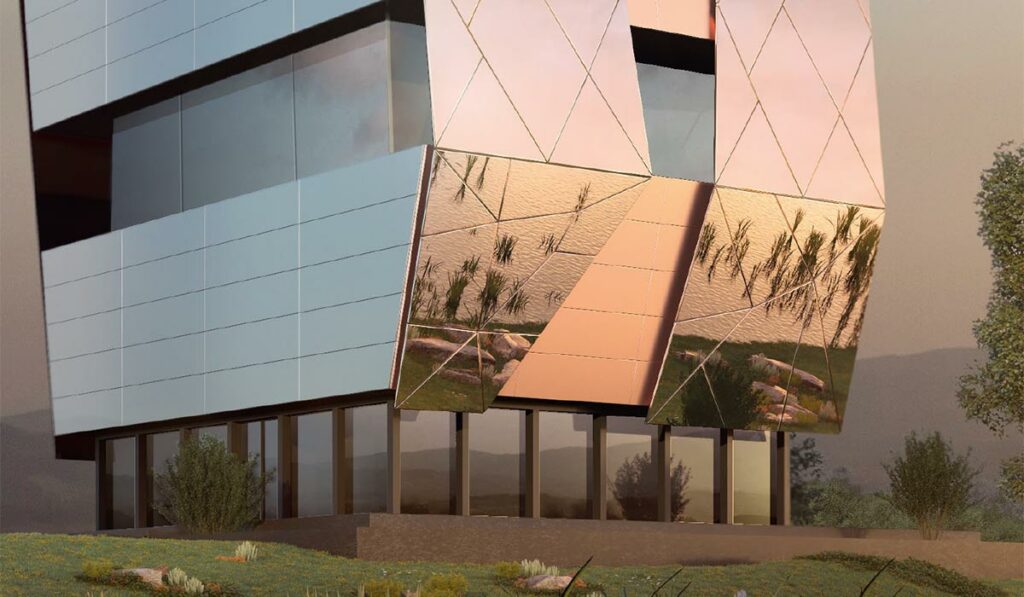

Building Design

From large expanses of water beside buildings, to reflective cladding on the structure itself, architects and designers have long used light and its reflection to create stunning effects. Thanks to the versatility of materials such as aluminium, architects now have the ability to make almost invisible constructions using highly reflective metal surfaces, or sympathetic structures incorporating different levels of opaqueness or perforated or mesh profiles.

Façade finishes in practice – Alanod’s anodised aluminium surfaces include the unique high specular (no glare) reflection of Alanod’s Gloss Mirror finish. Also, a wide variety of effects can be achieved by combining the same tonal colour base but using different finishes.

LED reflectors

Due to the fact that aluminium is such a good source of reflection of both visible light and heat, it is no surprise that it is the ideal material for use in light source reflectors. Lamps with aluminium reflectors project the heat forwards, so that the heat emissions from the back of the lamp are kept to a minimum. This makes them ideal for use in downlights or for other general lighting.

Aluminium reflectors in practice – Alanod’s MIRO® and MIRO-SILVER® DESSIN materials offer a total light reflection of 93% to 97% and due to the neutral colour reflection, all DESSIN products are ideal for all types of light with TL, HID or LED technology, regardless of their spectrum. Also, Alanod’s MIRO® CoM MC-PCB material has been specially developed for the LED baseplate industry and combines a reflection behaviour adapted to white LEDs with the optimum material hardness.

Solar reflectors

With COP26 highlighting the need for all of us to reduce our carbon emissions, solar energy generation is in the spotlight again. Solar reflectors are increasingly being used in solar energy applications such as evacuated tube collectors, parabolic trough power plants, micro parabolic troughs, photovoltaics, solar cookers and heliostats.

Solar reflectors in practice – Alanod’s range of solar reflectance coatings are layered on top of anodised aluminium or PVD coated aluminium and can be formed to suit any solar energy concentration requirement. Alanod’s Reflective 85 and MIRO-SUN® (used for CPC reflectors) and MIRO-SUN®PV (used as a concentrating reflector material for photovoltaic applications) offer total solar reflectance of either 85 % or 90 %.

So, whether you are looking the latest reflective finish for your building project, lighting system or solar solution, why not find out how Alanod can help. Please contact us here.