What can aluminium composite material be used for?

Aluminium composite material has become a versatile, durable solution widely used across many industries. Known for its lightweight structure, strength, and aesthetic flexibility, aluminium composite material offers a unique combination of aluminium sheets and a thermoplastic core. In this article, we’ll explore the many applications of the material and why it has become a go-to resource for both functional and creative projects.

An insight into the many applications of aluminium composite material

As one of the leading aluminium suppliers in the UK and overseas, we have spent over 40 years working closely with clients to produce quality metal surfaces tailored to their chosen applications. In more recent years, aluminium composite material has become one of the most commonly requested options, regularly used by interior designers, architects and more. To give more insight into how the material can be used in your next project, we’ve answered the most commonly asked questions among our clients.

- How is aluminium composite material made?

- What are the most common applications?

- What are the benefits of aluminium composite material?

- Why choose Alanod as your supplier?

How is aluminium composite material made?

Aluminium composite material, or ACM, is manufactured by sandwiching thin aluminium sheets around a plastic core before heating and pressurising the layers together. Various types of plastic cores can be used with a phenolic core, giving the ACM an A1 fire rating when used correctly. The process involves the following steps:

Preparation: The aluminium sheets are cleaned to remove contaminants and then treated to improve adhesion and corrosion resistance. Meanwhile, the plastic core is prepared for bonding.

Bonding: If necessary, the aluminium sheets are coated with paint or resin. The plastic core is then placed in the middle of two sheets using a continuous lamination process, where the materials are pressed together with strong adhesives.

Finishing: Once bonded, the new ACM is cut into the required sizes and shapes. The final panels are checked for quality, ensuring there is no delamination between layers and the surface coatings are intact.

What are the most common applications?

ACM has become a popular construction material due to its strong, lightweight, and versatile nature. The plastic core prevents warping and distortion, while the aluminium layers are designed to provide durability and rigidity, making it ideal for many applications, such as:

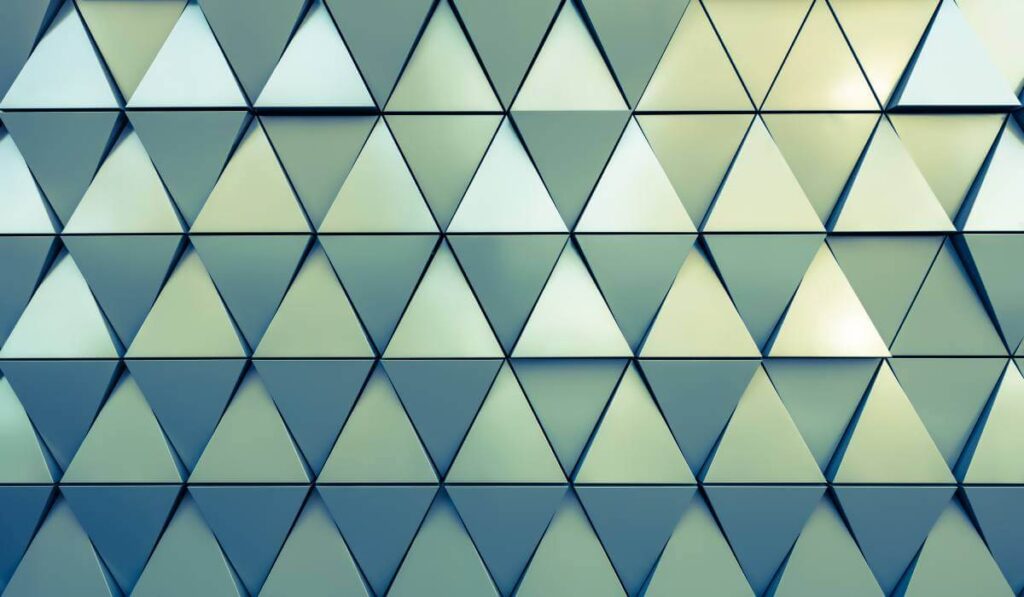

Architectural facades: One of the most popular uses of ACM is in building exteriors. It is often used to create modern, decorative facades on both commercial and residential buildings due to its weather resistance, lightweight and aesthetic appeal. Only ACM with a phenolic core should be used in this application, so make sure you ask for this when specifying.

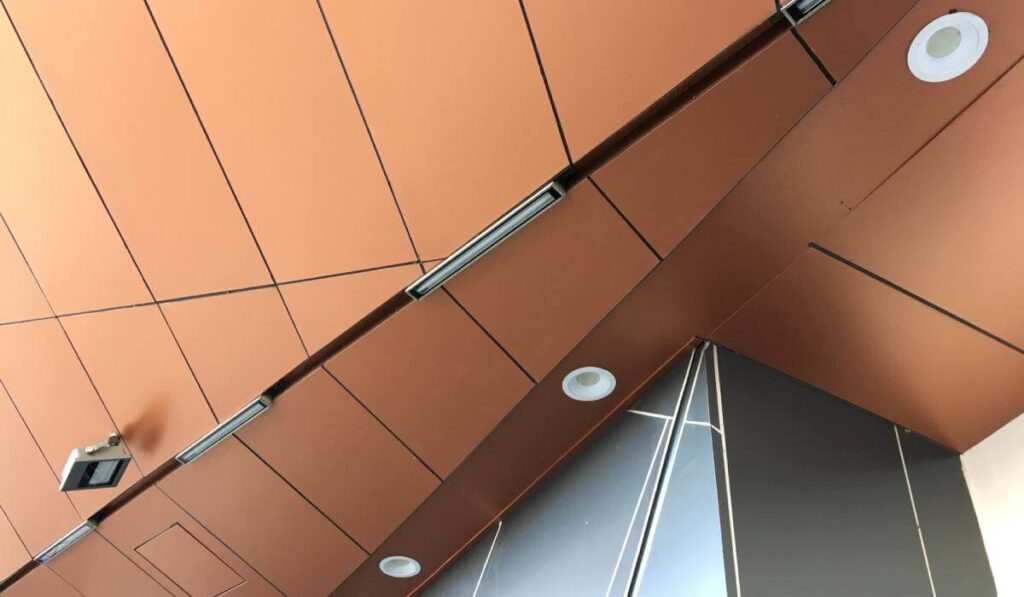

Interior design: From partitions to ceilings and intricate feature panels, ACM can be customised in a range of colours, textures and finishes, making it the perfect choice for creating a focal point in interior design.

Advertising signage: ACM is regularly used for signage, such as billboards and hoardings, due to its smooth surface, which allows for high-quality printing. Not only this, but its lightweight nature makes it easy to transport, mount and display.

Roofing and canopies: As mentioned previously, ACM is both strong and weather-resistant, making it an excellent choice for outdoor coverings such as roofing and canopies. Much like building exteriors, only ACM with a phenolic core should be used for this application, so it’s vital to ensure your specifications cover this.

What are the benefits of aluminium composite material?

Aluminium composite material offers several attractive traits, making it a popular choice in various industries. Learn more about the benefits below:

Excellent thermal and acoustic insulation: The plastic core inside ACM offers a great level of insulation, helping to maintain temperature control within buildings and reduce noise transmission, especially when the material is used as part of the cladding installation process.

Lightweight and easy to install: One of the key benefits of ACM is its excellent strength-to-weight ratio. It’s robust, durable and long-lasting yet incredibly lightweight, making it a quick and easy material to handle and assemble; this helps to reduce labour costs and time.

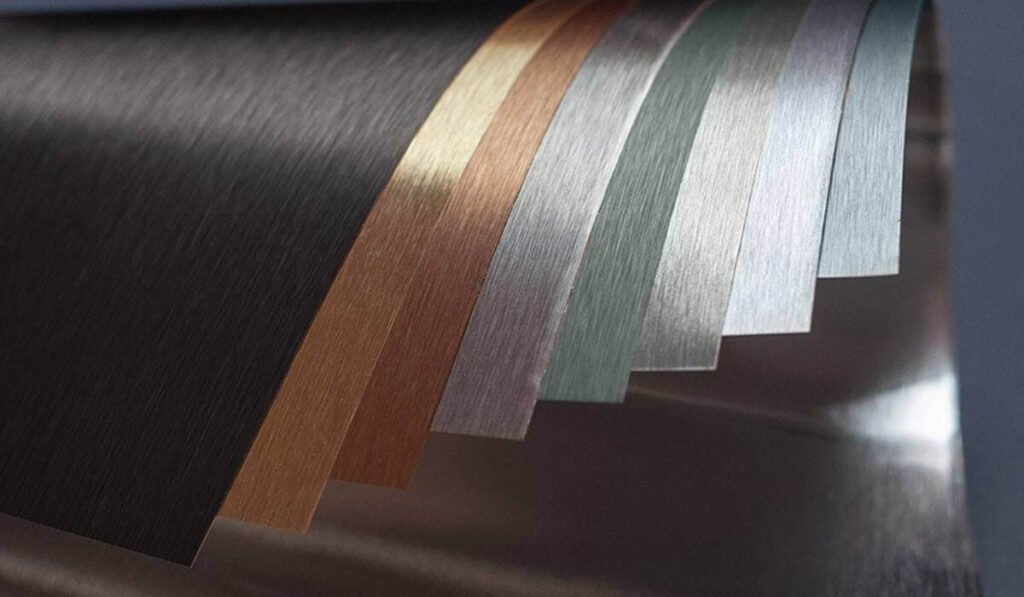

Versatile with many design options: ACM is available in a wide range of colours, finishes and textures, including matte, gloss, metallic and even woodgrain patterns. It’s also easy to cut, bend and shape, which, together, allows for endless design possibilities.

Environmentally friendly choice: Most ACM panels are fully recyclable, making them a far more sustainable option than other materials. Not only this, but many manufacturers, including our team at Alanod, use recycled materials during the production process, taking advantage of aluminium’s ability to be recycled indefinitely without losing quality.

Why choose Alanod as your supplier?

From working with Michael Kors on their flagship Shanghai store to Fulton Station in New York, our aluminium and metal surfaces have been used to design striking buildings across the globe. More reasons why clients continue to choose us as their supplier include:

Aluminium can be finished to spec: We offer anodising and lacquering as finishing options to customise the appearance of your aluminium. This allows you to choose from a range of colours in a matte, mirrored, satin or even two-tone effect. Learn more in our previous article.

Proactive approach to sustainability: When you choose Alanod as your supplier, you’re partnering with a company that cares deeply for the environment. We have implemented measures to reduce our carbon footprint during all manufacturing operations and use up to 90% recycled aluminium in our products.

Production to suit your demand: Our highly experienced team can accommodate anything from a single sheet to high-volume production runs with a quick turnaround. We offer the option of slitting rolls or cutting and guillotining materials to sheets.

ACM: A durable and flexible choice for any industry

It’s clear that aluminium composite material has proven itself to be an incredibly versatile and cost-effective solution for a wide range of applications. From architectural facades to signage and interior design, its attractive benefits make it a top choice for many industries. To discuss how ACM can be incorporated into your next project, feel free to contact our specialist team at Alanod. With many years of experience, we can tailor your supply to your needs and would happily schedule a visit to our UK headquarters to see how our metal surfaces are made.