How do our solar absorption surfaces work?

As a leading specialist in solar absorber surfaces, we have proudly refined a collection of high-quality, low-thermal emissivity coatings and surfaces for many applications. Offering industry-leading absorption performance, these products provide rates of up to 97% and emission rates as low as 4%. In this article, we delve deeper into the science behind solar absorption and how our materials can be integrated into your next project.

Make Alanod Solar your first choice for reducing CO₂ emissions

In the UK, businesses and individuals alike are encouraged to make more sustainable decisions to help the government meet their net zero target by 2025. One of the key players in this initiative is solar, whether it be solar PV (using sunlight to generate electricity) or solar thermal (using sunlight to generate heat).

Backed by award-winning solar absorption surfaces and decades of experience, we actively work with manufacturers to modernise solar technology. Learn more about our coatings and surfaces and their benefits below.

- What is solar absorption?

- What solar absorber surfaces do we supply?

- How can our products be used?

What is solar absorption?

Solar absorption is the process in which a surface or object retains solar radiation and converts it into heat. Here’s how it works: when sunlight strikes the surface, some of the energy is reflected, some is transmitted through the material, and the rest is absorbed. The absorbed energy is responsible for raising the temperature of the material, enabling energy conversion. These modern surfaces can be used for a number of applications, such as solar panels, solar thermal systems and building materials.

What solar absorber surfaces do we supply?

All backed by a 10-year outdoor material warranty, our solar absorber surfaces are available on a choice of metal substrates, allowing our clients to choose a product that fits their unique requirements. Our options are as follows:

eta Plus®

As a semi-finished product designed for solar thermal systems, our eta Plus® is ideal for:

- Full surface or strip absorbers

- Tube collectors

- Air and large-scale façade collectors

Boasting an incredibly high solar absorption rate of 96% and a low thermal emissivity of 4%, eta Plus® is based upon an aluminium or copper strip and is applied using a continuous PVD method in an innovative air-vacuum-air process. It is suitable for both laser and ultrasonic welding and can facilitate the production of high-performance collectors for solar cooling and process heat generation.

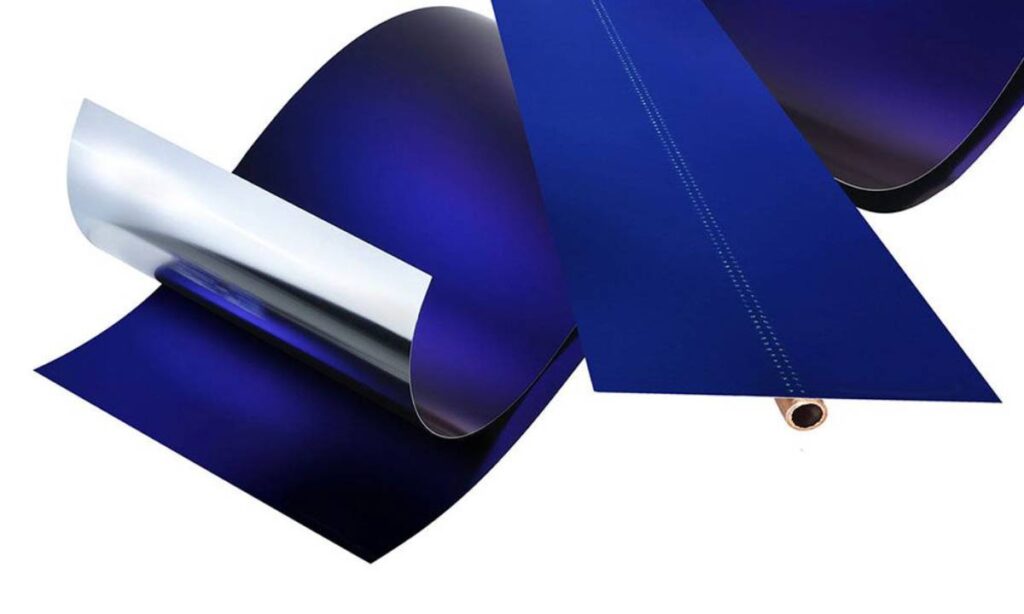

mirotherm®

Able to both absorb direct sunlight and diffuse radiation, mirotherm® is a specialised coating that has been used for over 20 years. Typically used in solar thermal systems, this product is based on an aluminium strip and is applied as a three-layer absorber system using a continuous PVD method. It boasts the following benefits:

- Low thermal emissivity

- Maximum solar absorption due to oxide absorption and antireflection coatings

- Resistance to external influences

- A laser weldable anti-corrosion coating

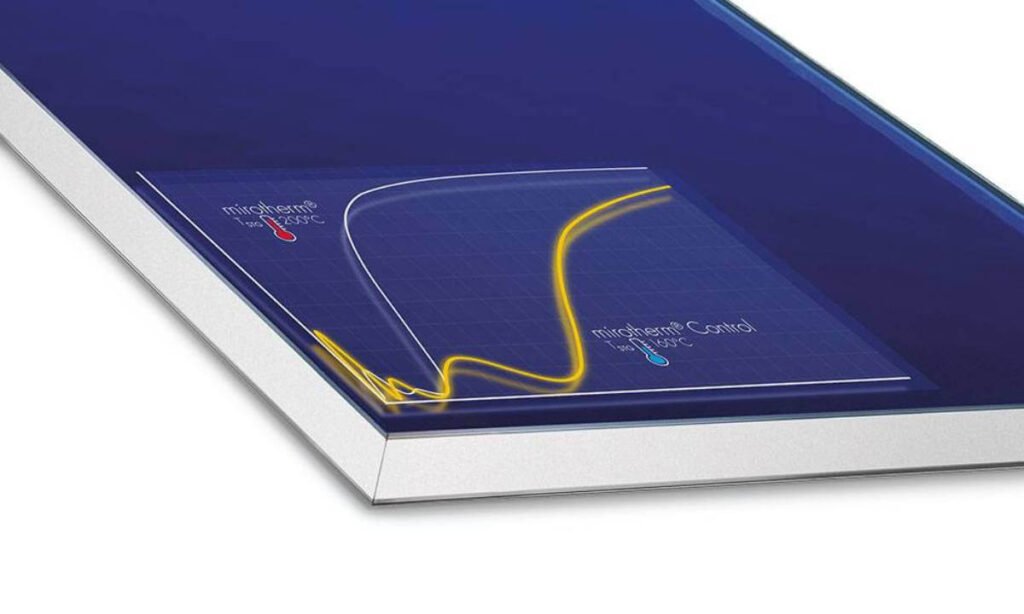

mirotherm® Control

Developed as a by-product of mirotherm®, mirotherm® Control utilises all of the benefits of its award-winning counterpart but with integrated overheating protection. It offers up to 97% solar absorption but with a 40°C lower stagnation temperature compared to standard systems, along with:

- Resistance to moisture and other external influences

- PVD vacuum coating

- A reverse-side treatment optimised for laser welding

mirosol® TS

If you are based in a region with high solar radiation, our mirosol® TS is the best-suited option. During its specially developed manufacturing process, mirosol® TS is created by applying a selective, hydrophobic lacquer to aluminium. This means that, for the first time, lacquers using the coil coating method are available for solar thermal collectors. More traits of this product include:

- Not sensitive to fingerprints

- High resistance to environmental pollution, salty air, moisture, condensation, oil and dirt

- Suitable for laser and ultrasonic welding

How can our products be used?

At Alanod, our solar absorption surfaces have been used across the globe for many years. They can be cut, shaped and coloured to suit the project specifications, making them a hugely versatile resource. Not only this, but we also utilise an environmentally friendly, low-emission manufacturing process, ensuring that we continue to remain a climate-neutral company.

From flat plate collectors to vacuum tube collectors, our products can be used in many applications. To give examples, some of our previous projects include:

Fulton Center, USA: 952 highly reflective perforated MIRO® aluminium panels were suspended from a stainless steel cable net, creating an intricate daylight-reflecting sculpture on the newly refurbished Fulton Center in New York. In a project led by James Carpenter Design Associates, the sculpture, named Sky Reflector-Net, has become a focal point in the transport and retail hub.

Dubai Sports Complex, UAE: Our mirotherm® surface layer was incorporated into the Dubai Sports Complex to provide enough energy to power the central heating, pool heating and solar air conditioning across the entire complex. The building, with a capacity of 15,000 spectators, features a 1.026 m2 solar field and has now become one of the most modern facilities in the world.

Contact us today to discuss how we can help you

If you are searching for a reliable, experienced partner who can fulfil orders with a quick turnaround, contact Alanod today. We would love to discuss your requirements in more detail and how we can tailor our award-winning products to meet your specifications. Backed by decades of experience, our team would happily recommend the best-suited option and invite you to our UK headquarters in Milton Keynes to learn how our solar absorber surfaces are manufactured.