Aluminium – Source it, Process it and Store it!

What does Brexit + the Ukraine war equal? Well, for manufacturers it equals challenge! Maintaining consistent supply and price of aluminium can be difficult.

In fact, previous ‘just in time’ stocking strategies, don’t work as well in a world where disruption has become the new normal. This has meant that many metal fabricators are re-evaluating supply chains, to ensure customers still get products as quickly as possible.

So, how can fabricators accommodate customer needs, whilst adapting to the challenges and opportunities that lie ahead? The answer lies in choosing a UK aluminium supplier that has put in place a robust aluminium sourcing, processing, and stockholding strategy.

Source it

Alanod, UK’s leading aluminium supplier, aims to source aluminium at the most competitive price and of the best quality for the price. To do this, Alanod sources from across the world.

- Sourcing for existing customers – To ensure an uninterrupted supply, Alanod also works closely with customers, using their forecasts to buy stock in advance. It is then stored and sold on at the price quoted at initial purchase.

- Sourcing for ad hoc requests – Alanod stocks more than 60 tonnes of commercial grade aluminium at any one time and has enough stock of anodised and PVD coated aluminium to cover six months of sales at any one time.

We stock all types of aluminium. Please click here to find out more.

Process it

Alanod places a priority on precision. That is why a highly experienced team monitor the machines throughout, to deliver consistent metal processing services with short turnaround times.

Scalable Solutions

- Larger slitting: the 1250 mm wide slitter can run thicknesses of aluminium up to 1.50 mm and steel up to 0.60 mm. The maximum input coil weight is 4500 kilos. Coils of 400 mm and 500 mm inside diameters can be slit with tight tolerances.

- Smaller slitting: coils of 400 mm and 500 mm inside diameters can be slit and narrow widths down to 10 mm wide processed (with narrower widths available subject to trial).

- Guillotining: the guillotine has a 2500 mm bed and can cut aluminium up to a thickness of 6.0 mm.

- Larger cutting: metal can be cut to length up to 1250 mm wide and 3000 mm long, all whilst achieving good flatness.

- Small cutting: coils can be cut into small sheets of a minimum of 80 mm wide to a maximum of 620 mm wide, with lengths up to 700 mm long. The flattening head also ensures very good material shape on aluminium and steel coils.

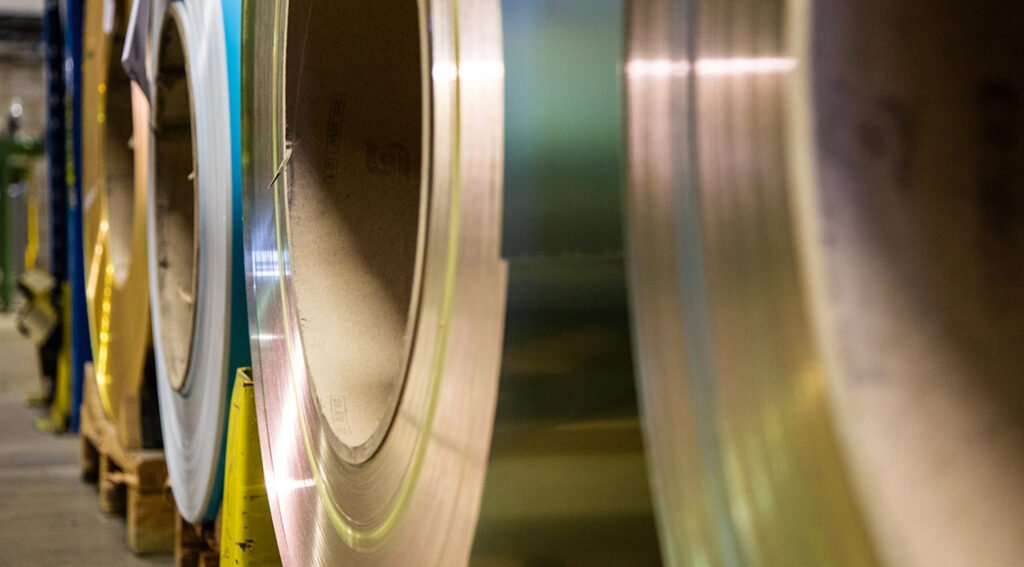

Storing it!

Alanod has capacity to store up to 1000 tonnes of commercial grade and anodised aluminium stock at the Milton Keynes depot. As well as packs of sheets, large volumes of coils are stored there and for speed of turnaround, there is racking for part coils, as well as full coils.

Available thicknesses

Alanod has from 0.3mm – 1mm in a range of silvers, colours and surface finishes. In addition, other thicknesses can be sourced from Germany, with 0.1mm and 0.2mm semi-specials available from Alanod Group, along with 1.0mm and 1.2mm silvers, colours and surface finishes.

1.2 – 2mm commercial grade aluminium is also available. It is ideal for general machining and jobbing applications such as back plates, aluminium non-decorative components and structural mounting products, where a uniformed surface finish is not as important as in anodised aluminium applications.

In this ‘new normal’ world we live in, why not manage some of the uncertainty by using a supplier who has bandwidth to deal with your fluctuating aluminium requirements?

We supply high quality aluminium and cost-effective metal processing services. Get in touch with us to find out more information.