Did you know we supply aluminium for solar panels?

The demand for solar panels continues to soar as the UK government recommits to its mission to reach Net Zero by 2025. This means more pressure than ever for panel manufacturers to source cutting-edge materials that enhance efficiency.

As the leading solar absorber surface specialists in the UK, the team behind Alanod continues to nurture strong partnerships with such manufacturers. In this article, we delve deeper into how we can help you leverage the unique characteristics of aluminium to optimise solar panel performance.

Proud to be the UK's leading specialists in solar absorbers

With worldwide coverage, our specialised solar absorber coatings and surfaces have been used in architecture across the globe. For example, the 15,000-capacity Dubai Sports Complex is designed with a solar field and solar panels that feature our popular mirotherm® surface layer, providing the facility with enough energy to power central heating, pool heating and air conditioning. This is just one impressive case study to prove the high performance of our solutions; learn more about how these can be integrated into your solar panel manufacturing process below.

Our surfaces are designed with solar success in mind

Having been established for over 40 years, innovation remains at the forefront of our production. Over the past two decades, we have fine-tuned our metal surfaces, developing a selection of solar absorber coatings that combine maximum solar energy absorption with low thermal emissivity. These include:

eta Plus®

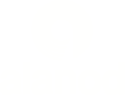

Available on copper or aluminium, our eta Plus® surface is a semi-finished product for solar thermal systems. Combining an impressively high solar absorption of 96% with a low thermal emissivity of 4%, eta Plus® is PVD vacuum-coated, ensuring enhanced durability and resistance to impact, chemicals and high temperatures. This surface is suitable for laser or ultrasonic welding and can be used for several purposes, such as:

- Flat-plate collectors with full-surface or strip absorbers

- Tube collectors

- Large-scale façade collectors

- Collectors for solar cooling and process heat generation

mirotherm®

As a specialised coating, mirotherm® is designed to absorb direct sunlight and diffuse radiation, making it an ideal choice for solar thermal systems. Having been used for more than 20 years, mirotherm® is created using a three-layer absorber system, which is applied onto an aluminium strip using a continuous PVD method. The benefits of choosing this product are as follows:

- Low thermal emissivity

- Up to 96% solar absorption (courtesy of oxide absorption and antireflection coatings)

- Resistance to external influences

- Added laser-weldable anti-corrosion coating

mirosol® TS

If you plan to manufacture solar thermal systems for regions with high solar radiation, we highly recommend opting for mirosol® TS. The unique trait of this product is its selective, hydrophobic lacquer, which is applied to the aluminium during the manufacturing process using a specially developed coil coating method. Other features of mirosol® TS include:

- Not sensitive to fingerprints

- High resistance to heavy environmental pollution, salty air, moisture, condensation, oil and dirt

- Low stagnation temperature

- Suitable for laser or ultrasonic welding

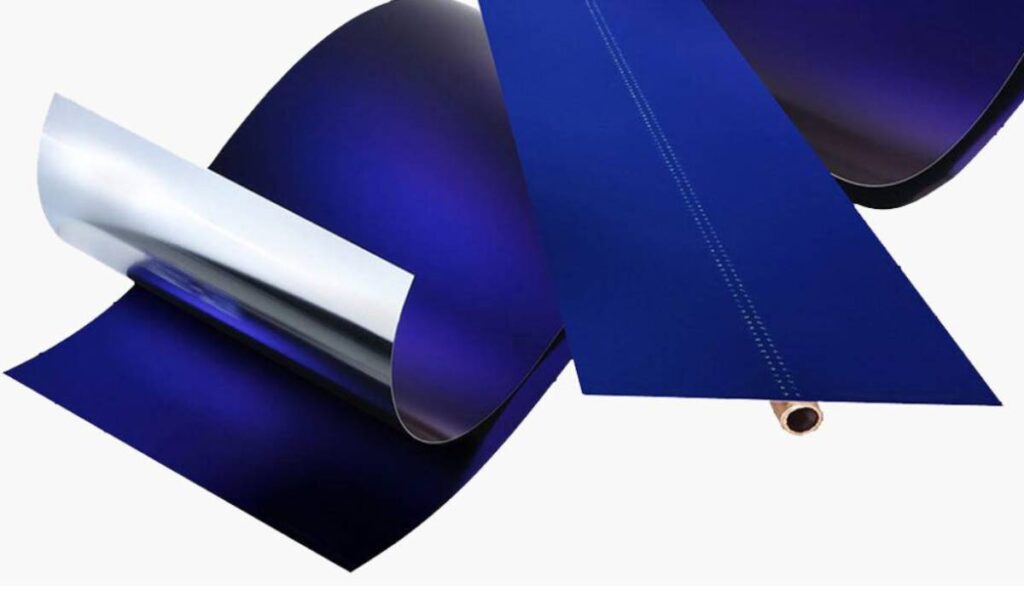

mirotherm® Control

mirotherm® Control promises all the same features as our best-selling mirotherm® but with the added benefit of protection against overheating. In terms of statistics, this product offers a slightly higher, up to a 97% solar absorption rate and a 40°C lower stagnation temperature than standard systems. It is PVD vacuum coated and designed with a reverse side treatment specifically optimised for laser welding.

What to expect from your partnership with Alanod:

Trusted by globally recognised manufacturers, we take a personalised approach, ensuring that the metal surface you receive meets your specifications to the finest detail. When choosing Alanod, we also deliver the following:

Environmentally friendly processes: We remain equally committed to minimising our carbon footprint as our clients. As such, we have implemented processes that comply with REACH, RoHS, WEEE and EoLV requirements while also incorporating recycled aluminium into many of our products.

Quick turnaround: We recognise the importance of reliability in partnerships, so we ensure a rapid turnaround within days of your order. Our UK operation can accommodate anything from a single sheet to high-volume production runs at your convenience.

10-year warranty as standard: All of our outdoor PV and thermal applications come alongside a 10-year material warranty as standard. For more information on our warranties, please do not hesitate to contact our friendly team.

Why not visit us to discuss your requirements?

When searching for new suppliers, we recognise the importance of gaining a comprehensive overview of the quality of the materials you invest in. For this reason, if you are interested in partnering with Alanod, we would happily invite you to our UK headquarters in Milton Keynes to discover how our metal surfaces are made. We have extensive knowledge of using aluminium collectors in solar panels and would love to discuss your unique requirements in more detail.